Sample Masters Logistics Literature Review

Here is a sample that showcases why we are one of the world’s leading academic writing firms. This assignment was created by one of our UK literature review writers and demonstrated the highest academic quality. Place your order today to achieve academic greatness.

Procurement of Raw Material to Aftab Textile industry in Pakistan

Chapter 2 : Literature Review

2.1 Introduction

This chapter defines supply chain management and its processes, along with focusing on the textile industry of Pakistan. Furthermore, strategic procurement management has been defined with the procurement process and its implications. The chapter also teaches logistics management and the importance of selecting the supplier/logistics approach, which could optimize production and operational efficiency.

The textile industry has been further evaluated through a critical analysis regarding the availability of resources and their allocation in the particular economy. The use of an efficient supply chain has been discussed, with its contribution to the organization’s overall efficiency.

2.2 Supply Chain Management and its Processes

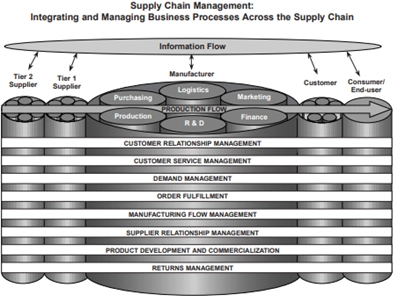

Supply chain management has been defined by Gunasekaran, Patel, and McGaughey (2004, p. 335) as a strategic planning process with a high emphasis on the decision making rather than on the operational systems. Another approach to the same concept suggests that supply chain management manages downstream and upstream relationships with the customers and suppliers for delivering high customer value and minimized cost to the supply chain. It has been stated by Skjott-Larsen (2008, p. 162) that there is a major problem associated with the conflict between the organisational boundaries and the supply chain processes.

Procurement, on the other hand, is considered to be one of the essential aspects of supply chain management, and with the evolving work circumstances, the organisations have now moved away from just purchasing the raw materials and finished goods to a broad supply chain management which inculcates risk evaluation of quality, and monitoring of suppliers.

Over time, companies have started outsourcing the processes of production to other external suppliers. The major reason for this inclination has cost reduction and increased flexibility of manufacturing (Lambert and Cooper, 2000, p. 70). The figure below depicts the integration and management of business processes across the supply chain, which provides a better understanding of how different aspects are interconnected in the supply chain.

Figure 1: Business processes across the supply chain

Source: Croxton et al. (2001)

2.3 Strategic Procurement Management

As discussed above, procurement is considered the essential aspect of the supply chain process. It could be divided into six basic methods that organisations use to fulfill their desired objectives. Strategic procurement management (SPM) is considered another aspect of SCM that assures effective cost control and optimum utilization of resources.

It has been observed in the recent past that organisations have increasingly faced the challenge of cost reduction along with improving the service level (Jacobs, Chase, and Lummus, 2014, p. 534). To serve the purpose, companies look forward to strategic and positive contributions in the sourcing and purchasing processes to enhance the company’s performance. Following are a few of the critical elements of strategic procurement management:

Supply base optimization is the first aspect, which develops buying leverage and achieves quality, delivery, cost, and supplier capacity advantages. This further enables efficient management of the supply base and enables enhanced purchasing practice. As O’brien (2015) stated, if the suppliers are flexible, highly responsive to product modification, and have high capability in design and engineering, it is likely to affect the performance of the company in a much positive manner.

Receive feedback on language, structure and layout

Professional editors proofread and edit your paper by focusing on:

- Academic style

- Vague sentences

- Grammar

- Style consistency

2.4 Procurement Process

The procurement process is highly essential for organisations, as an effective process may lead to an overall enhanced efficiency of the organisation. The process is further divided into steps that are defined below:

Need identification

The first step of the procurement process involves identifying the need for goods and services. In other words, it could be defined as the need identification and analysis. The individual is responsible for this need to assess the need and quantity of the required goods on time and make sure there is no shortage or surplus.

Selecting Vendor

After identifying the need, the next step is to explore and select vendors. It is considered one of the most critical tasks in the process, as the quality of goods highly affects its sales (Meehan and Bryde, 2011, p.100). The company must consider more than one vendor before deciding on selecting competitive pricing and quality goods.

Purchase Requisition

The third stage is submitting the purchase requisition. After selecting the vendor, the department needs to approve the requisition from the designated authority and then proceed with the process. The requisition must include all the necessary details and specifications of the desired goods.

Purchase Order

Then is the stage of creating a purchase order. This purchase order is given to the vendor for getting the required supplies. Vendors use this PO as a document of confirmation, upon which the supplier delivers the products to the company and then claims for its payment afterward through this PO.

Payments

After this, the next step in the process is to pay for the goods that are in-house. In this process, the payment must be made under the decided means of payment. The company must carry out this process with keen responsibility to mitigate the chances of any related adversities and satisfy the supplier by providing payments on the agreed timeline.

Record for Audit

The last stage of the process is to record for audit and establish necessary documents required by the audit department at later stages. In the purchase process, the department needs to carefully gather the important documents and maintain records of the transactions. Any ambiguities may be catered to efficiently at later stages (Meehan and Bryde, 2011).

2.5 Selection of Suppliers/Logistics Approach

To survive and operate in a highly competitive market, businesses need to retain current suppliers and find and discover new suppliers. According to Sawik (2013, p. 7010), various factors develop the need for new suppliers. The new suppliers may have certain capabilities and attributes that may not be present in the previous suppliers, such as improved production technology or streamlined processes, which may also reduce production costs. Chai et al. (2013) stated that the major reason for putting high emphasis on supplier selection is to avoid issues like late deliveries, poor quality goods, or increased costs for the business.

Schönsleben (2016) stated that logistics management is related to controlling the flow of services, goods, and information from different sources to their destinations. Several models have been developed to optimize logistics management, e.g., ERP, as the system integrates the data of logistics and process models, further allowing for the exchange of data through message exchange formats.

Pasanen (2015), on the other hand, suggests that even though these models enhance the performance of logistics management, they turn out to be costly, and their implications in organisations become difficult as proper training is required to operate these models effectively.

References

Chai, J., Liu, J.N. and Ngai, E.W., 2013. Application of decision-making techniques in supplier selection: A systematic review of the literature. Expert Systems with Applications, 40(10)

Croxton, K.L., Garcia-Dastugue, S.J., Lambert, D.M. and Rogers, D.S., 2001. The supply chain management processes. The International Journal of Logistics Management, 12(2)

Gunasekaran, A., Patel, C. and McGaughey, R.E., 2004. A framework for supply chain performance measurement. International journal of production economics, 87(3), pp.335

Jacobs, F.R., Chase, R.B. and Lummus, R.R., 2014. Operations and supply chain management. pp. 534

Lambert, D.M. and Cooper, M.C., 2000. Issues in supply chain management. Industrial marketing management, 29(1), pp.70

Meehan, J. and Bryde, D., 2011. Sustainable procurement practice. Business Strategy and the Environment, 20(2), pp.100

Monczka, R.M., Handfield, R.B., Giunipero, L.C. and Patterson, J.L., 2015. Purchasing and supply chain management. Cengage Learning.

O’brien, J., 2015. Category management in purchasing: a strategic approach to maximize business profitability. Kogan Page Publishers.

Pasanen, SR, 2015. Internal Supply Chain: Process and Performance Measurement Development.

Sawik, T., 2013. Integrated selection of suppliers and scheduling of customer orders in the presence of supply chain disruption risks. International Journal of Production Research, 51(23-24), pp.7010

Skjott-Larsen, T., Schary, P.B., Mikkola, J.H. and Kotzab, H., 2008. Managing the Global Supply Chain. Transnational Corporations, 17(1), p.161.

Zulfiqar, Z. and Din, N.U., 2015. Inflation, interest rate and firms’ performance: the evidence from textile industry of Pakistan. International Journal of Arts and Commerce, 4(2).

Frequently Asked Questions

Identify requirements, conduct market research, solicit bids, evaluate proposals, negotiate contracts, select suppliers, place orders, and manage supplier relationships.